Phoenix Laminator Comparison

Which Laminator Is Right For Me?

February 14, 2018

The Phoenix line of laminators from Southwest Binding & Laminating presents a diverse offering of operations, giving schools, government agencies, in-plants, print shops, and other businesses the power to create beautifully-laminated projects in-house. But which Phoenix laminator is right for your organization?

A Brief Comparison

The Phoenix 2700-DH is a thermal hot roll laminator ideally-suited for schools and offices. Clearly marked supply shafts make loading roll film easy for even the most inexperienced of operators, and adjustable speed settings allow for complete control over the laminating process. The 2700-DH runs films ranging from 1.5 to 3 mil thickness on a 1” or 2.25” core- often referred to as “school-grade” films. Large, 2.25” rollers ensure even heat distribution and a smooth, bubble-free finish. Projects up to 27” can be laminated with ease, perfect for educational projects and business needs. To see the Phoenix 2700-DH, click here

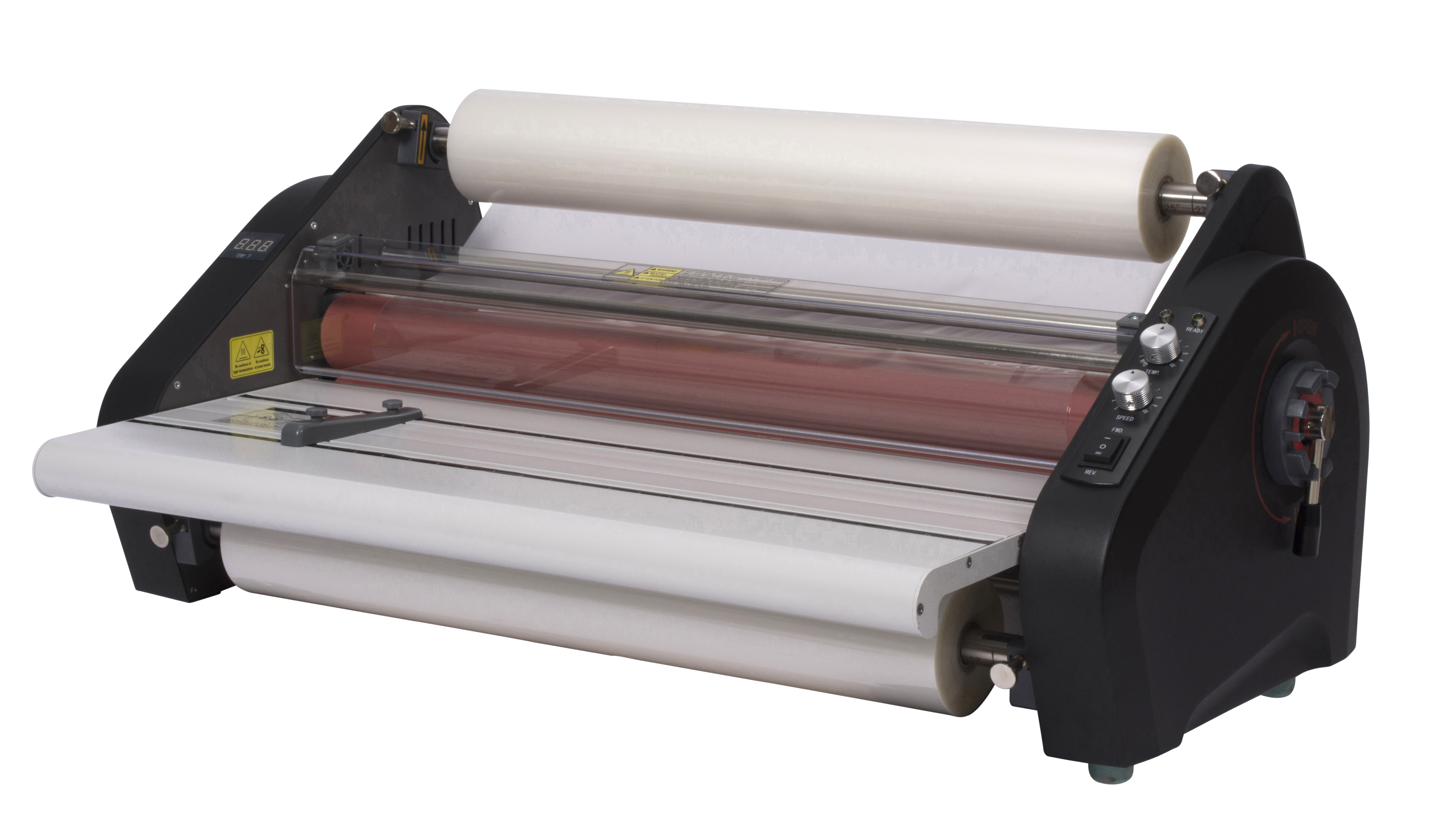

The Phoenix 2700-DHP is the production model of the 2700-DH. The 2700-DHP is intended for high-volume facilities needing an economical, table-top laminator. Building on the features of its little brother, the 2700-DHP adds extra functionality including adjustable temperature and the ability to run films up to 10 mil thickness. Operators may also gap rollers for easy mounting on substrates up to .25” thick and complete single or double-sided lamination- two features not available on the 2700-DH. To see the Phoenix 2700-DHP, click here

The Phoenix 4400-DHP expands the Phoenix line into wide format applications. High-volume in-plants and print shops will appreciate the ability to run up to 8 feet per minute and projects up to 44” wide. The 4400-DHP also adds independent heat and tension controls to the top and bottom rollers and allows for core sizes up to 3”. An extra layer of safety is added with an electronic photo eye, which automatically stops the rollers when a hand crosses the plane. Built for durability and longevity, the 4400-DHP provides years of reliable operation and beautiful results. To see the Phoenix 4400-DHP, click here

The Phoenix 44” Mounting Laminator presents a different solution for schools and print shops. Geared toward laminating pouches and pouch boards, the Phoenix 44” allows operators to insert prints into custom-sized pouches and run them through the machine- no need to deal with roll films! A simple, straight-forward control panel with two speed and temperature settings simplifies operation and allows users with all degrees of expertise to mount and laminate projects. Users may also run roll films, if desired, with the factory-installed roll kit. To see the Phoenix 44" Mounting Laminator, click here

Which Phoenix Is Right For Me?

For most schools and small offices, the Phoenix 2700-DH is the ideal choice. Teachers, administrators, and even students can operate the 2700-DH with minimal training and supervision. Easy loading and adjustable speed settings allow for quick, nearly effortless operation. All common “school-grade” roll films up to 27” wide are accepted, allowing for a wide variety of projects to be laminated without “breaking the bank.”

For print shops, in-plants, and high-volume production environments, the Phoenix 2700-DHP is the best option. Adjustable temperature settings and incremental grapping up to .25” make this unit more productive and functional than its little brother, the 2700-DH. Operators can mount posters and complete single or double-sided lamination up to 27” wide with minimal effort as well as run films up to 10 mil thickness.

For high-volume, wide format applications, the Phoenix 4400-DHP is the unit for you. High-volume in-plants and print shops will enjoy adjustable speed and independent heat and tension controls for the top and bottom rollers. The 4400-DHP can complete posters, signs, displays, graphics, and more up to 44” wide with films up to 10 mil thickness and core sizes up to 3”. Incremental gapping up to .25” thick is accomplished with the simple turn of a knob, allowing for easy mounting on substrates. Safety features such as a safety shield and electronic photo eye ensure safety, making the 4400-DHP a great choice for both experienced and novice operators.If you want to avoid roll film, the Phoenix 44” Mounting Laminator is a great alternative. Designed for running laminating pouches and pouch boards, the Phoenix 44” allows operators to bypass roll film entirely and still achieve professional results. Astoundingly simple and easy to use, the Phoenix 44” features only two speed and temperature settings- perfect for operators of any experience level. Mounting on substrates up to .25” thick and up to 44” wide, the Phoenix 44” presents a versatile, wide-format solution for any school, office, or print shop. A factory-installed roll kit also allows for roll films to be run if so desired.

The Bottom Line

No matter what your needs are, you can’t go wrong with a Phoenix laminator. Still unsure which unit is right for your organization? Give us a call and talk to one of our friendly and knowledgeable sales representatives to determine the best fit for your specific situation!

You can reach us by phone at: 1-800-325-3628

Or via email at: sales@swplastics.com

Thanks for reading!

Source: Southwest Binding & Laminating