Shrink Wrapping Basics For Businesses

February 2, 2018

If you’re a business owner or production manager, you know just how much of a pain shipping, storing, and packaging products can be. You’ve probably spent countless hours and dollars on solutions that take up too much space or cost too much money, leaving you to wonder: “Isn’t there a better way?”

Thankfully, there's shrink wrapping.

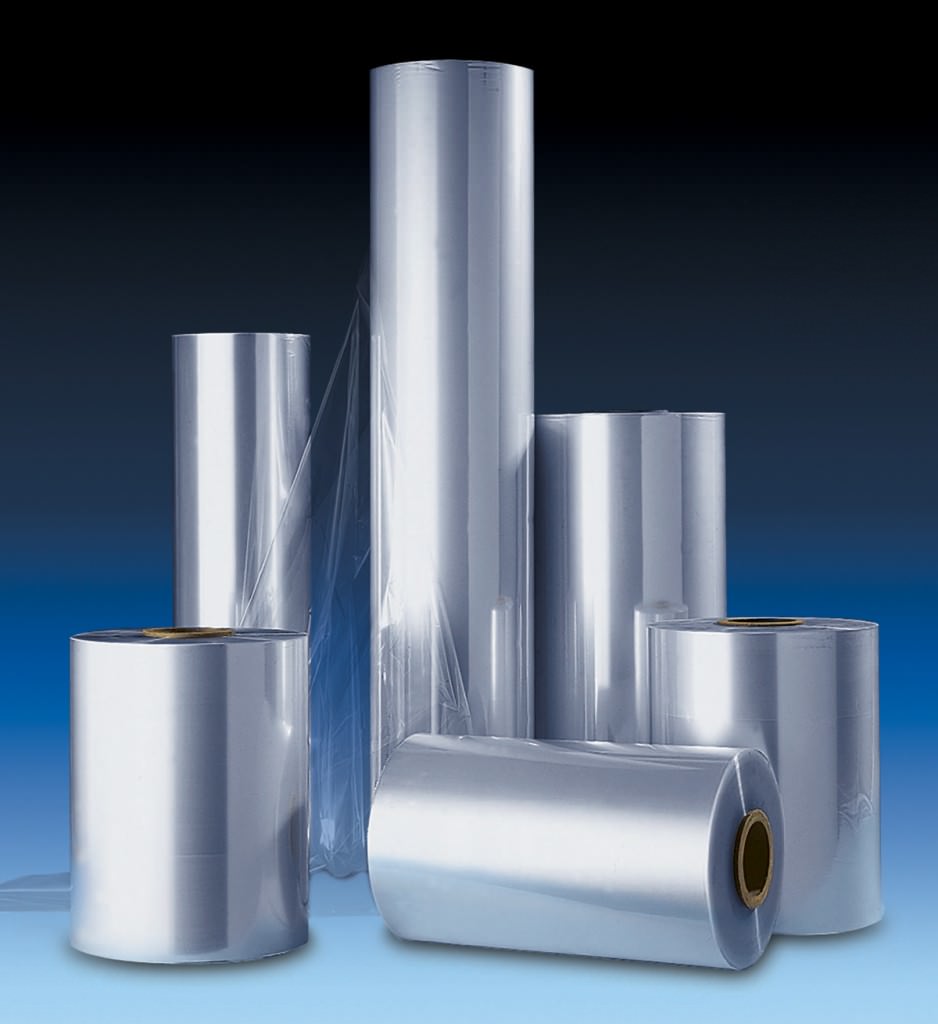

Shrink wrap is a heat-activated, plastic film that is durable, tear-resistant, and cost-effective. Shrink wrap films work by applying heat to the plastic, which then shrinks around the item being wrapped, resulting in a secure, tamper-evident seal. Available in a wide variety of widths, lengths, and thicknesses to accommodate products of all shapes and sizes, shrink wrap film is used to package, store, and transport products ranging from foods and beverages to household goods and auto parts! All that you need to begin is film and a heat gun.

To shrink wrap, simply fold shrink wrap film around your product. Then, make even passes over the film with a heat gun, rotating the item as you go. There is also more automated equipment which can accomplish this task with a heat chamber or heat tunnel. The heat activates the film’s shrinking properties, creating a secure seal within seconds. Shrink wrapped items are held tightly in place and protected from moisture, dirt, and other contaminants that may damage your products.

Because shrink wrap film conforms to the exact shape of the product being wrapped, less space is consumed by big, bulky boxes or containers. This saves businesses money on storage, shipping, and material costs. As a result, shrink wrapping provides an affordable, versatile solution for just about any industry.

Depending on the volume of your business, there are a variety of shrink wrapping devices available to speed up production. Heat guns are ideal for low-volume, manual applications. However, busier businesses will do better with an I-Bar or L-Bar sealer. Industrial environments will save the most time and money by using a shrink chamber or heat tunnel machine.

Which shrink wrap film is right for me?

Southwest offers two options for shrink wrap film- PVC and polyolefin. To decide which choice is best for your business, you must first understand the properties of each of these films.

PVC is short for “polyvinyl chloride” and is a very common solution for wrapping non-food items such as books, CDs, and other small objects. PVC film is very responsive to heat- even a blow dryer can activate the plasticizer! This means that shrink wrapping can be accomplished in seconds, saving your business time and money. However, the downside of PVC film is the smell of this product is not optimal in a work environment.

Although cheaper than polyolefin, PVC film is not ideal for every application. PVC is not approved for direct contact with food due to the chloride in its chemical composition, so there must be a barrier between the film and the food. Also, PVC’s responsiveness to heat allows it to more easily expand and contract than polyolefin, making it brittle over time. This means that prolonged exposure to a warm environment or sunlight may cause the seal strength of PVC to weaken.

Polyolefin is the more preferred type of shrink wrap film, used for a wide variety of applications such as: toys, auto parts, cleaning supplies, medication, printing/paper products, and more. Polyolefin film is FDA-approved for direct contact with food, as it contains no chlorides. It is also less responsive to heat than PVC, meaning that polyolefin requires a higher sealing temperature or long exposure to the heat source. As a result, polyolefin will not soften or harden in changing conditions and can be stored in more locations. Polyolefin film also creates a stronger seal than PVC, lending itself to a wider variety of uses.

The biggest drawback to polyolefin film is its cost. Its excellent sealing and shrinking abilities equate to a higher price than PVC film. Extremely cost-conscious users may opt for PVC as a result if they are not producing food or large products that require the safety and enhanced protection provided by polyolefin film.

How do I get started?

Are you ready to save your business time, money, and space but are still unsure which shrink wrapping method is right for you? Contact one of our expert representatives to help determine the best fit for your specific needs!

You can reach us by phone at: 1-800-325-3628

Or via email at: sales@swplastics.com

Thanks for reading!

Source: Southwest Binding & Laminating